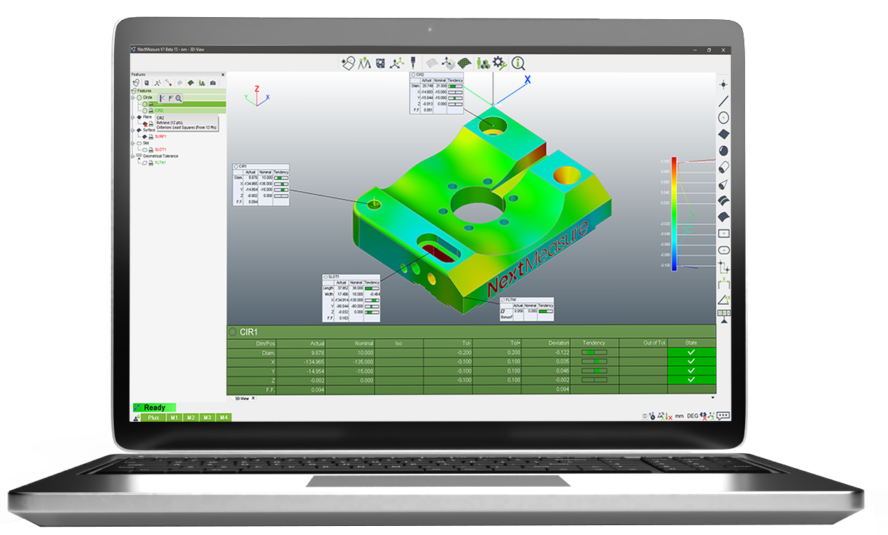

Looking for an easy 3D inspection solution?

The NextMeasure

difference

Without being an expert, you can carry out the simplest to the most complex measurement scenarios.

WHAT

NextMeasure is the 3D inspection software which makes quality control more productive for everyone.

It is perfectly suited for efficient 3D inspection in SMEs and large groups of manufacturing sectors such as metal working, aerospace, automotive and equipment goods.

It’s an easy-to-use and powerful tool for all teams: manufacturing, quality control and design departments.

WHY

NextMeasure benefits

Quick & efficient quality control

With its user-friendly interface and application-oriented features, control and validate manufactured parts and assemblies in the blink of an eye.

Get best-in-class speed, reliability & robustness for efficient quality control.

Easy to learn, easy to use - Everyone can perform inspection tasks

No need to be a metrology expert to use NextMeasure, get trained in less than 1 hour!

Free & unlimited access to online training: step-by-step tutorials & complete webinars.

Get also all necessary support online with FAQ, user forum and advanced chat (PLUS Version).

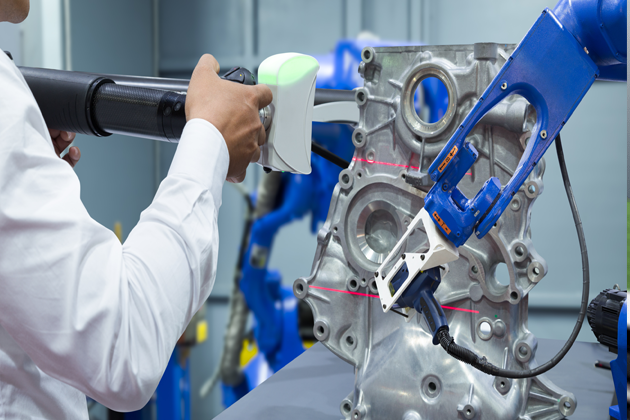

Adapted to your needs

Use NextMeasure on all type of sensors and portable measuring devices (arms, laser trackers, structured light scanners) of all brands.

Use NextMeasure everywhere: on your shopfloor, in your quality control room and in your offices for offline analysis.

Thanks to the embedded setup assistant, it is very easy to connect your device

Competitive & evolutive price

Choose the NextMeasure version that best fits to your needs: FREE version for day-to-day inspections, PLUS version for advanced inspections as you grow.

What do you get with NextMeasure?

Every feature you need for productive quality control

3D Probing

Simplify your inspection tasks with action-oriented buttons, clear menus and application-oriented functionalities.

3D scanning

Unlimited point cloud acquisition, meshing, filtering, color mapping, point cloud export, … all the features needed for powerful 3D scanning inspection are included.

Measurement efficiency & productivity

Repeat your inspection scenario with measurement replay functionality.

Get assistance while measuring with probe and optimize your probing strategy.

GD&T

Get the best of GD&T, based on the latest ASME and ISO standards.

Geometric Dimensioning and Tolerancing is nowadays a must-have in the manufacturing industry. Get GD&T light with NextMeasure FREE, full GD&T with NextMeasure PLUS.

Analysis and reporting

Detailed view, raw data information to automatic stickers & complete reports, get everything you need for detailed analysis of manufactured part and extended reporting to exchange on dimensional analysis with your partners.

Universal software

Operate all your portable scanning & probing devices and sensors through direct hardware plug-ins and measurement file import.

Use all open & proprietary CAD formats.

Export data, point clouds and reports in various formats.

Hardware & sensors compatibility

Articulated arms: FARO, ROMER, HEXAGON, KREON, MITUTOYO and others

Laser tracker: API, LEICA, HEXAGON, FARO and others

Structured light scanners: CREAFORM, HEXAGON and others

Touch probes: FARO, HEXAGON, KREON, RENISHAW and others

Laser scanner: FARO, HEXAGON, KREON, NIKON and others

Minimum settings for small CAD

Minimum configuration for small CAD (< 100Mb) with a simple shape (sheet metal) and

without point cloud:

- Windows 10 64-bits

- Dual core processor >2.2 GHz

- 8 GB memory RAM mini

- Graphics Card: 1 GB mini, supporting OpenGL 2.1

This information is purely indicative, because it can vary according to the quantity of data input formats.

Testimonials

« Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. »